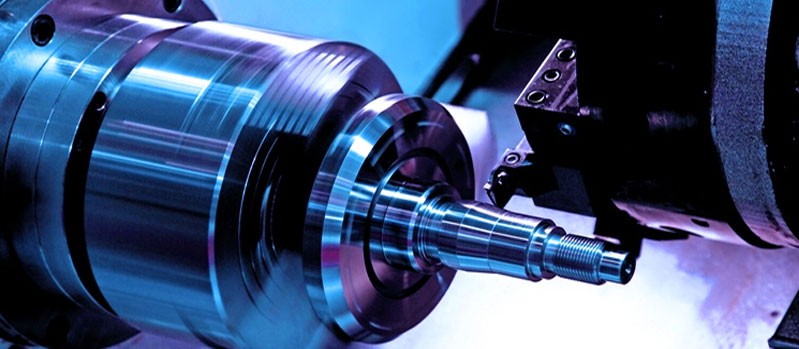

Precision Machining is a process to remove material from a workpiece while holding close tolerance finishes. Giken has been involved in precision machining industries for more than 30 years. With these years of experience and knowledge, Giken is able to provide world class engineering solutions to a wide range of industries that include Medical, Automotive, Semiconductor, Home Appliances, Toy, Pump, Motor, Oil & Gas, Aerospace and etc.

Giken has a wide range of first process facilities and secondary in-house process to provide a complete service with shortest lead time for our clients. For first process, we have a number of facilities such as, Escomatic, Super Precision Lathes, High Speed Cutting, Multiple Axis Machining and others technology. Our secondary in-house process included in-house Heat Treatment, Centreless & Cylindrical Grinding, Barrel Polishing, Knurling, Ultrasonic Degreaser, Straightening, End/Radius-Grinding, Drill & Tap and Oven Annealing.

With the facilities above, we are able to produce and achieve;

- Material Diameter : 0.5mm to 80mm

- Length : 0.8mm to 1000mm

- Diameter Tolerance : 0.002mm (2 Micron)

- Roundness : 0.0003mm (0.3 Micron)

- Surface roughness : Ra0.05

- Run-out : 0.01mm

- Concentricity: 0.001mm

All above mentioned measurement we are able to measure with our in-house calibrated measuring equipment. Our experience give us advantages on sourcing for all kinds of material standard from reliable mills all around the world. We welcome all standards of material and we will do the sourcing to fulfil your requirement.

Please contact us for details of this service and a full list of available task fulfilments.